Indicators on Digital Printing You Should Know

Indicators on Digital Printing You Should Know

Blog Article

The 4-Minute Rule for Digital Printing

Table of ContentsThe 4-Minute Rule for Digital PrintingA Biased View of Digital PrintingDigital Printing for BeginnersThe 45-Second Trick For Digital PrintingGetting My Digital Printing To WorkDigital Printing Things To Know Before You Get ThisThe Best Guide To Digital PrintingDigital Printing Things To Know Before You Get This

Personalization additionally permits companies to stick out in a jampacked market by producing special marketing materials that distinguish them from their rivals. Among the primary advantages of digital printing is the ability to print variable information. Each published item can be distinct, allowing businesses to produce personalized advertising and marketing products that speak directly to their target audience.Digital printing also allows for personalization in the layout of advertising products (Digital Printing). With digital printing, companies can produce layouts that are one-of-a-kind and customized to their specific needs.

The smart Trick of Digital Printing That Nobody is Discussing

By publishing smaller quantities of marketing products, businesses can lower waste and stay clear of the demand for excess supply. Digital printing is likewise versatile.

By utilizing various products and styles, organizations can produce distinct advertising and marketing products that attract attention from their competitors and bring in interest from their target audience. Digital printing likewise uses uniformity. With traditional printing approaches, there is often variant in between prints because of differences in ink protection, pressure, and various other elements.

This uniformity can aid develop customer trust fund and reliability, revealing that the business is committed to supplying top quality materials. Uniformity is particularly important for businesses that wish to construct customer count on and trustworthiness. By ensuring that every print corresponds, businesses can reveal that they are dedicated to supplying top notch products and taking note of the information.

Everything about Digital Printing

Furthermore, digital printing produces less waste due to the fact that it can publish as needed and in smaller quantities, decreasing the need for excess inventory and materials. Digital printing also uses less power contrasted to typical printing approaches. Digital printers do not call for as much power to run, as they do not require to warm up as much or utilize as much power to run.

An Unbiased View of Digital Printing

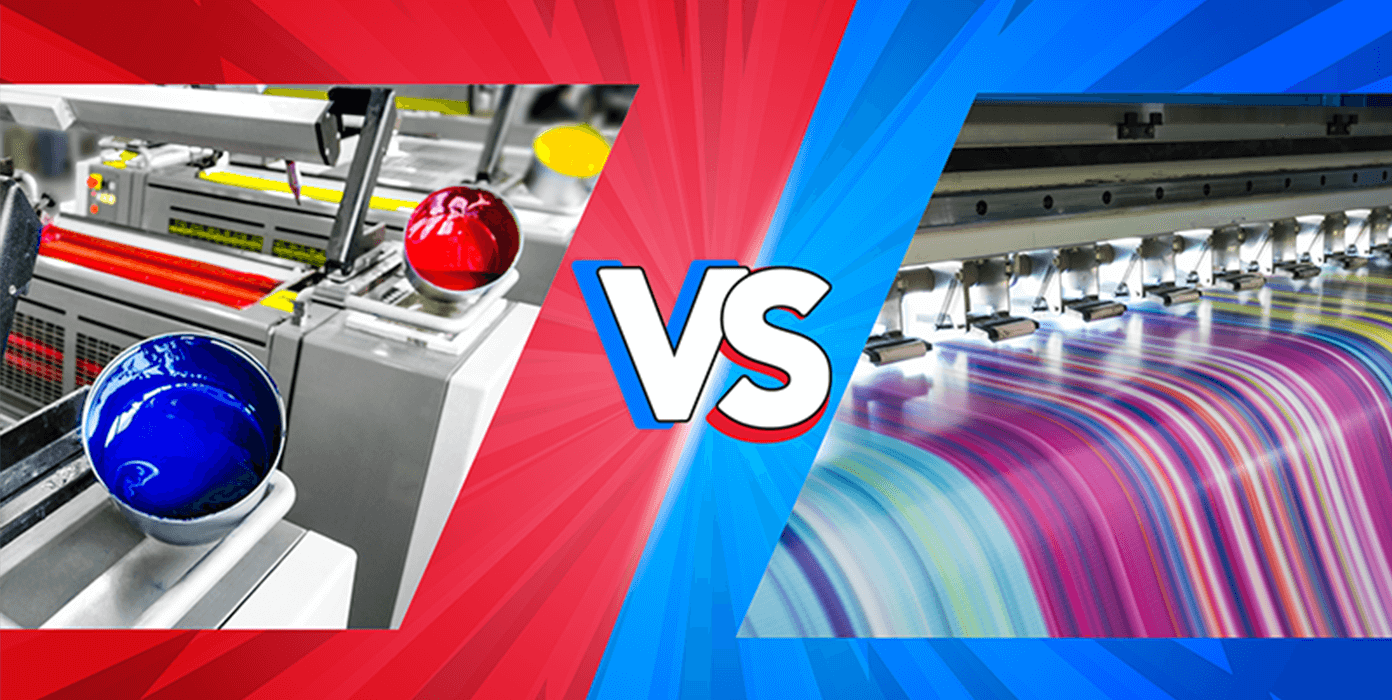

Countered printing requires a plate for each color printed. Typical offset printing is a print method that utilizes aluminum plates to transfer ink onto a rubber sheet (typically referred to as a "covering").

How Digital Printing can Save You Time, Stress, and Money.

Offset printing permits for a broad array of print materials to be made use of throughout production. The high-grade link pictures produced via offset printing make it the favored method, specifically among visuals designers, when looking for the best color recreation, detail, and professional-looking prints.

For electronic inkjet printing, ink is transferred straight onto the surface area. Instead than depending on light weight aluminum plates and rubber coverings to transfer an image, digital printing utilizes liquid ink throughout production.

Digital Printing Fundamentals Explained

Much better color integrity describes both the accuracy of the colors and their balance in the style. Because offset printing can mix custom-made shade inks for each and every job, it will naturally obtain the shades spot-on. Works similarly well on nearly any type of product. Reliable, remarkable photo high quality. Depend on countered printing for tidy, distinctive types and images without streaks or areas.

It costs a great deal to start an offset task. You have to spend money right into producing the plates, which requires time. Once you have actually invested it, all of the products are prepared to go, and you'll spend less on big countered jobs than a digital print, which is about the very same per piece no matter how big the task my link obtains.

Each print is identical. You run the risk of less odd variations brought on by imbalances in water and ink. Digital printing is much less pricey for low-volume tasks. The rate per unit goes down for electronic printing, so eventually, they crisscross. Altering details within a single print work. Claim you were printing out postcards advertising a show.

Some Known Questions About Digital Printing.

While digital printing or inkjet printing is the preferred selection in the present times, there are engaging reasons to transform from countered to digital printing systems. When publishing countered or electronically, critical decisions and processes are involved in color matching.

Whichever the instance, the shade will require to be matched. Shade matching of digital printer ink is no more testing with dyes and pigments. Industrial inkjet printing offers adaptability for printing on many various substratums. Digital printing is optimal for customers that do not call for longer runs and warehousing materials.

One advantage of digital printing is selecting from a variety of electronic substratums. With balanced out printing, substrates compose, usually, 30% of the price of the job. With digital printing, the cost of the substrate in the overall job is minuscule. This allows for more choices than ever before, and that benefits marketing professionals and organizations.

The Ultimate Guide To Digital Printing

drop-on-demand is the second printing technology to think about. Continuous inkjet systems call for significant upkeep, even more driver training, and greater downtime. Tools prices in inkjet printing are much lower than offset printing as there are no plate-making, plates, and press expenses. Beyond the resources expense, the prepress devices and printing machine require very knowledgeable drivers in balanced out printing, which adds labor prices.

Report this page